It is 3:47 AM inside a power plant. A fabric expansion joint in the main exhaust duct tears open without warning. Hot gas begins moving into the wrong spaces and sensors alert every operator on duty. A shutdown timer is already in motion and every minute counts. This type of event requires a dependable response that protects uptime and keeps the facility moving forward. This is the moment when Zepco LLC activates a system that focuses on precision, clarity and immediate action. Their approach is recognized across many industries because it supports fabric expansion joints replacement fast with structure and confidence.

The following is the four hour emergency protocol that guides plant teams from crisis to restoration with an organized process that feels steady and professional from the first call through final testing.

Hour 1: Emergency Assessment and Mobilization

Minute 0 to 15: Initial Contact and Failure Diagnosis

The moment the emergency hotline rings, Zepco LLC places the situation into motion. A specialist collects essential information that forms a clear picture of the failure. Plant personnel describe the condition of the damaged joint, current temperatures, pressures and the general behavior of the system. The team also confirms the location of the joint and any access limitations inside the facility. This creates a complete understanding so the response crew arrives prepared for immediate action.

Minute 15 to 45: Technical Specification and Material Confirmation

The team verifies exact measurements of the joint and confirms the required materials for the specific application. Power generation, chemical processing and industrial heating each demand fabric solutions that respond well to their environments. Stock availability is checked and confirmed so the crew brings the correct components. When unique conditions appear, the team identifies safe alternatives that still support fabric expansion joints replacement fast without slowing plant operations.

Minute 45 to 60: Deployment Initiation

The emergency crew departs with the materials and tools required. Transportation is arranged with routes that allow timely arrival. Safety alignment with the plant begins during this period so the team can move into the site quickly. Everyone understands their role and follows a clear plan that supports a confident and steady workflow.

Hour 2: On Site Evaluation and Interim Stabilization

Minute 60 to 90: Physical Inspection and Safety Assessment

Once on site, trained technicians complete a visual and technical assessment of the failed area. They evaluate the condition of the surrounding duct or pipe sections and identify anything that requires reinforcement. This step includes a full safety review and confirmation of hot work requirements. With this information, the team and plant personnel share a unified understanding of the next steps.

Minute 90 to 120: Temporary Containment and System Protection

If the system benefits from temporary support, the crew installs protective seals or coverings that help maintain stability until the replacement is completed. Temperature and pressure monitoring is adjusted to match the updated conditions of the system. During this period, the team also finalizes all specifications for the replacement joint that will be installed during the next hour. This keeps fabric expansion joints replacement fast and organized without interruptions.

Hour 3: Rapid Replacement Execution

Minute 120 to 150: Removal of Failed Joint

The failed joint is removed with a process that protects surrounding equipment. Any remaining debris is collected and cleared from the work zone. The technicians prepare the duct or pipe ends so the new joint sits correctly and provides the required movement and seal performance. Every action follows a carefully structured procedure that supports both safety and speed.

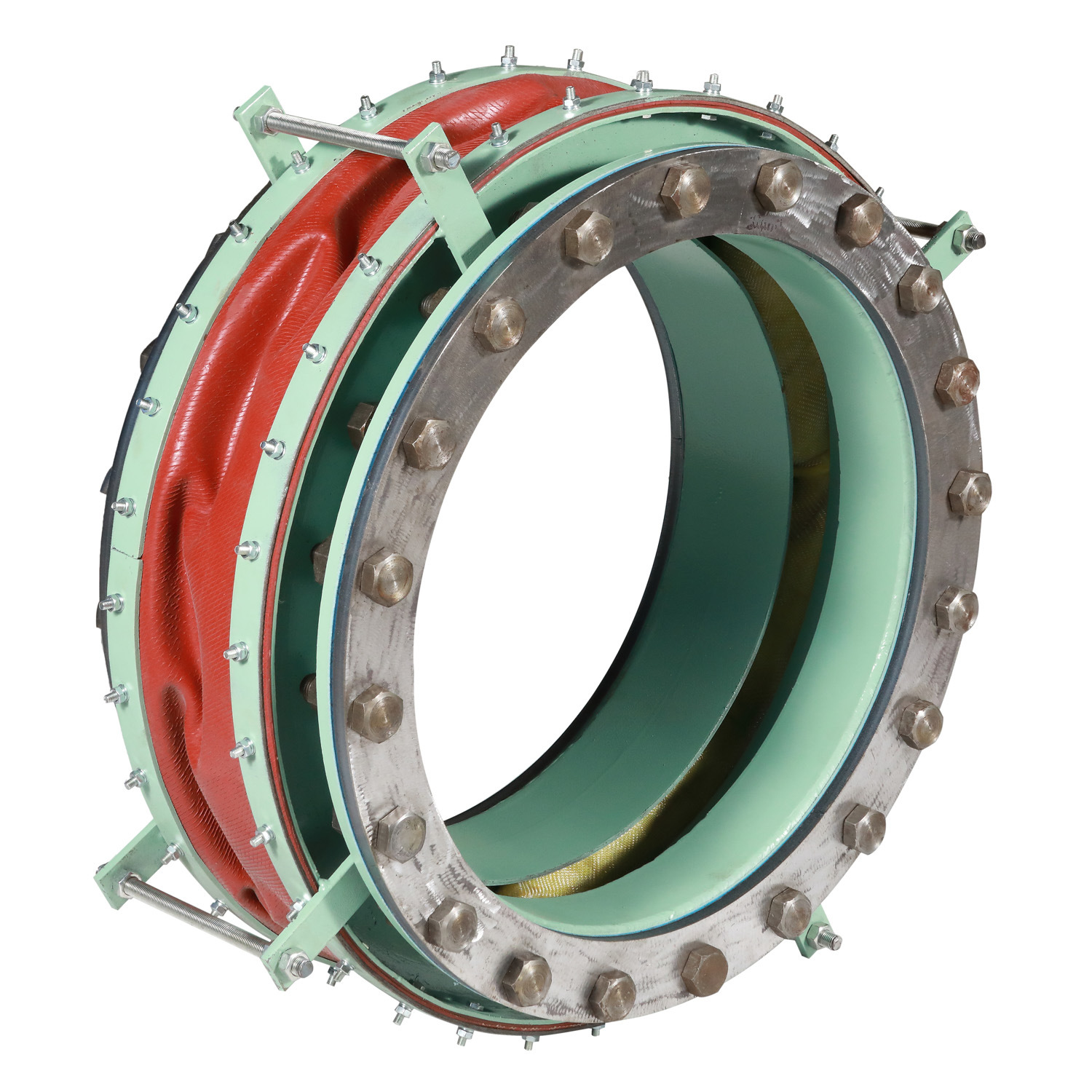

Minute 150 to 180: New Fabric Expansion Joint Installation

The new joint is positioned with accuracy and secured using the correct hardware. Each connection point is checked for alignment and stability. Layers of insulation are added when the system requires thermal protection. Every stage includes quality checks that confirm readiness for startup. Zepco LLC brings experience from many industries and this supports fabric expansion joints replacement fast with confidence and clarity.

Hour 4: System Restoration and Validation

Minute 180 to 210: Pre Startup Testing

Before the system resumes operation, technicians review every connection point. Leak testing and movement verification confirm that the joint meets required performance standards. The safety systems for the area are reactivated and the work zone is cleared for controlled startup.

Minute 210 to 240: Controlled Restart and Monitoring

The system ramps up with a planned increase in temperature and pressure. The team watches the behavior of the new joint and the surrounding equipment. Vibration, alignment and movement are checked during the warm up. Once everything shows stable performance, operational approval is given and the system continues running as expected.

Post Protocol Support

We remain present during the initial hours following installation to verify that the joint operates smoothly under normal load conditions. Ongoing oversight is provided to ensure each component maintains consistent performance as systems come online. This early monitoring supports a steady transition into full operational cycles. The facility team benefits from dependable guidance that reinforces confidence in the new installation.

Conclusion

This four hour emergency protocol exists to bring order and confidence to urgent situations. Zepco LLC also supports planned maintenance programs that improve long term reliability for fabric expansion joints across many sectors. Facilities that prepare in advance with a qualified vendor gain faster response times and a smoother path to restoration during critical events. When plants require fabric expansion joints replacement fast, Zepco LLC remains ready to support with structure, experience and a dependable process.