In industrial environments, where even brief equipment failures can lead to costly downtimes, fabric expansion joints replacement fast is a critical asset. From power plants to refineries, unexpected issues in the system can arise anytime—whether it’s an unexpected leak or damage from high-stress conditions.

Preparing for these emergencies ensures minimal operational interruptions and maximizes safety, which is where Zepco’s rapid response services come into play.

In this guide, we’ll explore why fast fabric expansion joint replacements are essential for emergency preparedness, practical steps to prepare, and how Zepco’s expertise can provide the support your facility needs in critical situations.

The Importance of Rapid Fabric Expansion Joint Replacement

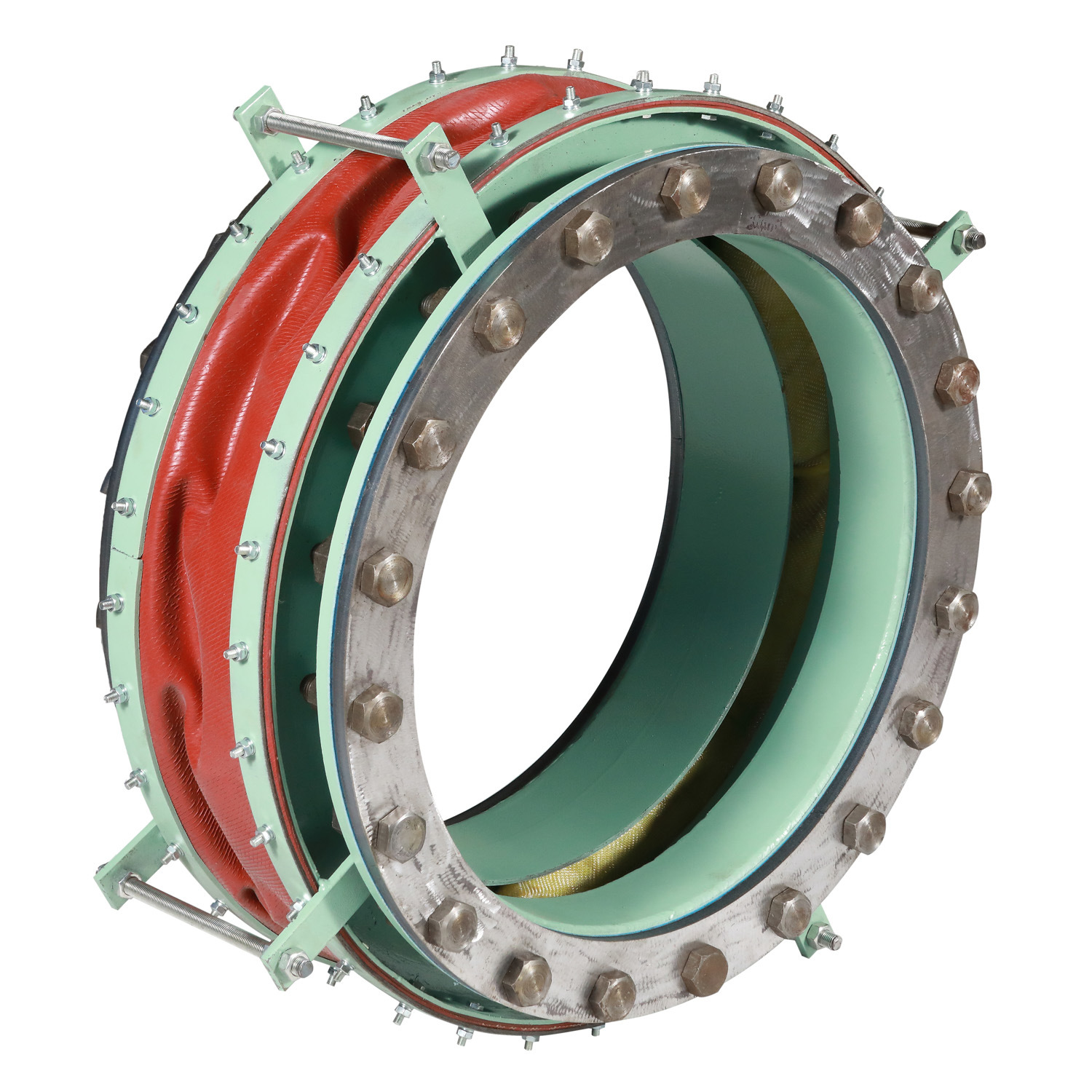

Fabric expansion joints are integral to absorbing movement, vibrations, and thermal expansion in piping and duct systems.

But when they wear out or fail due to harsh conditions, it’s essential to have a reliable, quick replacement plan.

How Fast Replacement Minimizes Downtime:

- Avoids Production Interruptions: A damaged expansion joint can stop operations instantly, halting production and impacting deadlines. Rapid replacement gets systems back up and running quickly.

- Enhances Safety: Defective joints can create hazardous conditions, including gas leaks or overheating. Fast replacement reduces risks and keeps employees safe.

- Protects Equipment: When fabric joints aren’t replaced promptly, stress can transfer to surrounding equipment, causing additional wear or even permanent damage.

In industrial emergencies, response time is crucial. Having a plan for fabric expansion joints replacement fast can transform a potentially costly situation into a manageable one.

Preparing for Fast Fabric Expansion Joint Replacement

Every facility can benefit from a strategy focused on emergency preparedness.

Here’s how to set up a practical plan:

1. Regularly Inspect Joints for Wear

Routine checks can reveal early signs of wear, cracks, or other vulnerabilities. By identifying issues early, you can avoid emergencies by replacing joints proactively or preparing for a swift response if they worsen.

- Tip: Schedule inspections quarterly or after extreme weather events, high-output production runs, or significant operational changes.

2. Keep Replacement Joints in Stock

When an emergency strikes, waiting for parts is a common and costly delay. Stocking fabric expansion joints, or knowing which sizes and configurations to order, saves valuable time.

- Tip: Zepco offers guidance on the types and sizes of fabric joints that are most commonly needed, helping facilities keep the right stock on hand.

3. Develop an Emergency Action Plan

When issues arise, every minute counts. Having an emergency response plan for replacing expansion joints, including contacts for quick service providers like Zepco, ensures minimal downtime and smooth execution.

- Tip: Make sure team members know the response steps, from shutting down affected areas to contacting Zepco’s rapid response team.

4. Partner with a Trusted Replacement Provider

In emergencies, working with a reliable provider is essential. Zepco’s fabric expansion joint solutions are tailored to minimize downtime while offering high-quality, durable materials that withstand extreme conditions.

Zepco’s Expertise in Fast Fabric Expansion Joint Replacement

When an emergency hits, Zepco offers a fast, dependable solution.

Our team specializes in fabric expansion joints replacement fast, with tailored services that prioritize your facility’s needs, safety, and operational goals. Here’s how Zepco stands out:

On-Demand Support for Emergencies

At Zepco, we understand the urgent need for immediate support. Our team is available around the clock, providing on-site assessments, and solutions within tight timeframes to minimize interruptions and help you recover quickly.

High-Quality Fabric Joints for All Conditions

Zepco provides durable, high-performance fabric expansion joints that withstand high temperatures, chemicals, and pressure changes. This ensures that replacement joints will not only perform well but will last longer, even under challenging conditions.

Efficient Installation Services

Fast response also means efficient installation. Zepco’s team is trained to handle installations swiftly and accurately, reducing setup time and getting your facility back to optimal performance with minimal hassle.

Signs You Need Fast Fabric Expansion Joint Replacement

Recognizing the signs that a fabric expansion joint is nearing the end of its life can allow for quicker, pre-emptive action and prevent emergencies altogether.

- Visible Damage: Fraying, holes, or visible tears in the fabric.

- Changes in Flexibility: Stiff or cracked fabric, indicating it’s become less effective at absorbing movement.

- Leaks or High Noise Levels: Whistling, hissing, or pressure loss can indicate a joint is no longer sealed effectively.

- Excessive Heat Transfer: Increased surface temperatures near the joint can signal failing insulation properties.

If you notice any of these signs, it may be time for fabric expansion joints replacement fast. Acting before a complete failure can save time and resources in the long run.

Emergency-Ready with Zepco’s Fast Fabric Expansion Joint Replacement

Fast, effective emergency response makes all the difference in industrial facilities where uptime is crucial. Zepco’s commitment to fabric expansion joints replacement fast means you have a partner you can count on when it matters most.

By preparing ahead and partnering with Zepco, you’re not just responding to emergencies; you’re building a proactive strategy to keep your operations resilient.

Ready to reinforce your emergency response with rapid replacement solutions?

Contact us today, and let us help you stay prepared for any situation, ensuring seamless operations with expert support you can rely on.

Comments are closed.